I have been having some problems with the stepper motor and the Sparkfun stepper driver and have finally gotten it all straightened out. The motor was having periods when it would sputter, misstep, and sometimes not even run at all. I finally reached the conclusion that the motor or the controller was bad. Since the motor was from surplus, I decided to replace it. It was not very expensive and I was able to find an exact replacement online so I did it. The new one seemed to work better, for a while, but then I started having similar problems. I was looking into replacing the controller but, in doing this, I found some documentation on the board that I had not seen before. In the margin notes, I found the recommendation that some of the inputs that were not being used in control be either connected to ground on Vcc (+5vdc). The ones that were listed included one to put the controller to sleep and another that was a reset. The third was called PFD and I did not examine its function closely but, I had not seen anything in the sample hookup documentation about these pins. However, I tied all three to Vcc and now everything is working fine.

Now I have a nearly completed mount. I just have to put on the part that will hold the camera and I will be ready for some field testing. However, first some more bench testing was in order. I attached a limit switch to allow the door to have a seekable home position. This ties to one of the Arduino inputs and, by doing a little testing. I found this to be a highly repeatable location even though the button I used seemed to have a lot of play to it. A second button was attached to be a command switch. The command button switches the program between the different modes: STANDBY, which is the default start mode and where the controller is just waiting for input, RETRACT, where the door is seeking the home position, READY, where the door is home and waiting to start tracking, and TRACKING mode.

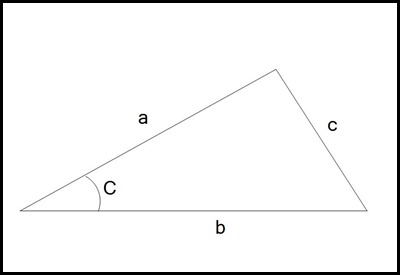

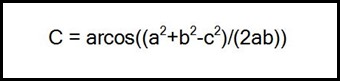

After installing the home position switch, I had to repeat some of my measurements to determine the lead screw leg distance for the home position (see the last installment to see where this measurement is used in the calculations). I then went back and ran the test to measure the angles of individual steps that should each open the door in one degree increments. I got much better measurements, although still not as perfect as I would expect. More testing and measuring might be in order.

Next, I created a test for the command button. The button throws an interrupt to the Arduino board. This sets a flag that is then detected and reset in the program. Everything checked out fine so I incorporated the command button into the final Barndoor program and implemented each of the modes of operation. Finally, I was able to run the door through its paces. The flowchart follows. Click on it for a bigger view.

Next, I will have to finish up the packaging for moving to the field. I think I will mount the circuitry on the bottom of the mount and then route the cabling so it does not get snagged. I will likely also mount the lighting where it is easily viewable. My power supply for the field will be an automotive jump starter and tire inflator which has both a USB power port and a 12V power port. The USB port will power the Arduino through its USB port and 12V will power the stepping motor circuit. I have already tested the door using this power source and it is robust enough for use in the field.