Monday, January 26, 2026

Ambient Weather Rain Gauge

Monday, November 24, 2025

New Automenorahs and Communications

Thursday, September 07, 2017

The Barndoor Tracker Revisited

Well, I got a chance to put the Barndoor Tracker to use this summer. On August 21st, I was privileged to observe the Great American Eclipse from Glenrock, WY. The weather was sparkling, except for some high, wispy clouds that showed up just in advance of the eclipse and continued to grow a bit right after. However, photographic opportunity was perfect and the eclipse occurred right on schedule.

In advance of the eclipse, I did a considerable amount of testing and work to get the tracker properly aligned to track the sun. I learned a lot about both astrophotography and the tracker. One thing is that the tracker has got a bobble to it. It tracked ok but not perfectly. The sun stayed in frame but it would move a bit from one picture to the next. I was taking pictures every two minutes and the sun would move one way and then the other. I think that there were two things that contributed to this. One was that the geometry is too complex. I plan to rebuild it this winter to align the pivot points with the lead screw. This will get rid of some of the calculations needed and also will make it easier to get the pivot points straight. That leads to the other possible problem, that at least one of the pivot points is not straight, which makes the door open at an inconstant rate.

The other thing I learned about the tracker was how to get it aligned. I had to do it the night before by sighting on the North Star (Polaris) with my camera attached to the tripod and shooting a timed exposure of about 30 second. Then I zoomed in on the image and adjusted the tripod to get the star to align perfectly with the center of the image. When this was correct, and the tripod was completely locked down against movement, I retired and, in the morning, attached the tracker to the tripod without disturbing it. After this, it tracked quite accurately, except for the aforementioned wobble.

So the other day I was at the Fry’s here in Wilsonville, Oregon, where we are visiting now that the eclipse is memory and photos, and I bought a Raspberry Pi. I guess I will be exploring this next and figuring out what I can do with it. Fun.

Friday, May 19, 2017

Barndoor Tracking Mount Part 5

The tracker is pretty much finished now and has been field tested with excellent results. The electronics are mounted on the bottom and covered by a shell, the lighting has been added where it is visible from the top, and I have added bubble levels to aid in getting the platform level and at the proper angle for the latitude. I have run some test programs which run the platform through some known angles and it came out spot-on. The only difficulty I have had is in setting up the tracker on the exact polar axis. So far, I have not used it in a location where I could see Polaris. I have used a compass and measuring angles with my phone to set it up, with mixed results. There is a little movement of the images but not much, many because I performed mostly short exposures. However, to aid in this setup, I have added two bubble levels. One is attached along the long axis to get the bed level. The other is adjustable on a protractor so it can be adjusted for the current latitude. Then I should be able to use the bubbles to set the correct angle. I would still need Polaris to site on or a compass to get the azimuth angle correct. This would also have to be the way to set up in daylight (as I will be using this tracker during the solar eclipse this summer).

Here are some final pictures.

Friday, December 16, 2016

Barndoor Tracking Mount Part 4

I have been having some problems with the stepper motor and the Sparkfun stepper driver and have finally gotten it all straightened out. The motor was having periods when it would sputter, misstep, and sometimes not even run at all. I finally reached the conclusion that the motor or the controller was bad. Since the motor was from surplus, I decided to replace it. It was not very expensive and I was able to find an exact replacement online so I did it. The new one seemed to work better, for a while, but then I started having similar problems. I was looking into replacing the controller but, in doing this, I found some documentation on the board that I had not seen before. In the margin notes, I found the recommendation that some of the inputs that were not being used in control be either connected to ground on Vcc (+5vdc). The ones that were listed included one to put the controller to sleep and another that was a reset. The third was called PFD and I did not examine its function closely but, I had not seen anything in the sample hookup documentation about these pins. However, I tied all three to Vcc and now everything is working fine.

Now I have a nearly completed mount. I just have to put on the part that will hold the camera and I will be ready for some field testing. However, first some more bench testing was in order. I attached a limit switch to allow the door to have a seekable home position. This ties to one of the Arduino inputs and, by doing a little testing. I found this to be a highly repeatable location even though the button I used seemed to have a lot of play to it. A second button was attached to be a command switch. The command button switches the program between the different modes: STANDBY, which is the default start mode and where the controller is just waiting for input, RETRACT, where the door is seeking the home position, READY, where the door is home and waiting to start tracking, and TRACKING mode.

After installing the home position switch, I had to repeat some of my measurements to determine the lead screw leg distance for the home position (see the last installment to see where this measurement is used in the calculations). I then went back and ran the test to measure the angles of individual steps that should each open the door in one degree increments. I got much better measurements, although still not as perfect as I would expect. More testing and measuring might be in order.

Next, I created a test for the command button. The button throws an interrupt to the Arduino board. This sets a flag that is then detected and reset in the program. Everything checked out fine so I incorporated the command button into the final Barndoor program and implemented each of the modes of operation. Finally, I was able to run the door through its paces. The flowchart follows. Click on it for a bigger view.

Next, I will have to finish up the packaging for moving to the field. I think I will mount the circuitry on the bottom of the mount and then route the cabling so it does not get snagged. I will likely also mount the lighting where it is easily viewable. My power supply for the field will be an automotive jump starter and tire inflator which has both a USB power port and a 12V power port. The USB port will power the Arduino through its USB port and 12V will power the stepping motor circuit. I have already tested the door using this power source and it is robust enough for use in the field.

Monday, December 05, 2016

Barndoor Tracking Mount Part 3

So I had to back up on something I posted last time. I showed the stepper motor with an 8mm screw and two intervening shaft couplers. Well, after ruminating on it a bit I realized that the shaft coupler that was flexible would not work with my design. I needed one that was ridged, otherwise too much play would be added into the system and accuracy would suffer. I knew that the motor shaft is 1/4 inch and the lead screw is 8mm so I looked for a coupler that would match those sizes and, surprise, there is such a thing. $6 later I have one. So now I was ready to start building the mount. The two “doors” are 3/4 inch oak and there are three hinged areas that hold the two doors together and also allow the motor and lead screw nut to stay aligned as the door is opened and closed. I showed a picture of this design in the last post so I took to building. The RV resort where we live in the winter has a nice woodworking shop so I had everything I needed.

I started cutting and shaping and, with a couple of restarts due to misplaced components and the purchase of another piece of wood to make the hinges, I was able in a few days to have put together the mount. Here are some pictures of the components and the final assembly.

|  |

|  |

|  |

|  |

Next came a test of this set up. I created a program for the Arduino to move the door in one degree increments from the closed position to the maximum open position. I immediately found a problem. Measurements showed it to be opening too far, about 1.3 degrees per increment. I did some modeling of my code in an Excel spreadsheet and it looked good. After some more testing I finally discovered that the lead screw, which I could have sworn was a three-start thread, was actually a four-start thread. This meant that instead of moving 6mm per revolution, it was really moving 8mm per revolution. This made a big difference and I was able to just change a variable in the program to correct it.

I forgot to mention that a crucial part of getting the door to open correctly was making accurate measurements of the finished device. I need to know the exact dimensions from the main door hinge center to the motor block hinge and the lead screw nut hinge. I also need to know the distance from the lead screw hinge center to the center of the screw and the same from the motor hinge to the center of the motor shaft. With all of those dimensions I can there create a formula that gives me the angle between the two door halves and can compute how far the lead screw nut has to be pushed out to open that angle by a specific amount. The same formula then can be used to determine the rate at which to step the motor to get the door to match the sidereal angle of the earth.

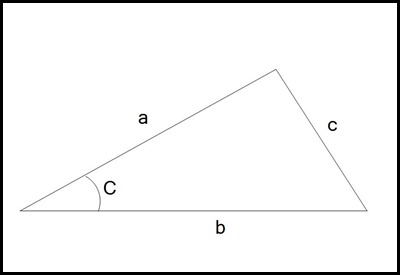

Now, examine this diagram:

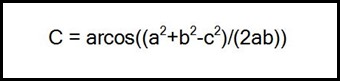

If the vertex of a-b is the main door hinge, the vertex of a-c is the lead screw nut hinge, and the vertex of b-c is the hinge of the motor block, then the angle C is defined by the formula:

So “a” and “b” are measured constants and “c” is variable as the lead screw moves. However, the screw does not pass thru these points so there is another formula to find “c” for different steps on the lead screw. The geometry of the lead screw with respect to “c” is described in the following diagram and formula:

The lead screw nut (“n”) leg and the motor base (“m”) leg are always at right angles to the lead screw (“L”). Note: this is the reason the flexible motor shaft coupler was not appropriate. So the Pythagorean Theorem is used to determine the length of “c” depending on the position of the nut on the lead screw. By combining these two formulas the angle “C” can be determined for any particular step of the motor and can be matched then to the sidereal angle of the earth starting at the home or closed position of the door.

Next, I have to attach a switch to mark the home position and program the tracking algorithm for the Arduino. More on that in the next installment.

Wednesday, November 23, 2016

Barndoor Tracking Mount Part 2

Ok, the lead screw and nut I ordered has arrived. The good news is it looks like it will work just fine for what I am doing although the shaft connector that came with it to go from the 8 mm shaft to the motor is too small for the motor, which has a 1/4 inch shaft. But, the shaft coupler I already had for the old lead screw is just the right size to match up with the other coupler so, with a cut off 3/16 inch screw, I was able to get it all together.

The screw turns out to have 3 starts and a 2mm pitch which results in 6mm travel per revolution. I will probably drive it in 1/4 steps from the EasyDriver so it will result in 800 steps per rev and so 0.0075mm per step. The step interval should be around 300 milliseconds, depending on what the actual final dimensions of the door are.

I should now be able to begin fabricating the door itself. I have a piece of 3/4 inch oak for that purpose. The working drawing is below. I will hinge the door on one side and will also hinge both the nut on the top and the motor on the bottom. I believe I have the formulas worked out correctly to compute the step interval to get it to follow the sidereal angle of the earth. I will do some testing after I have the structure built to see how accurate I am. The final proof will of course be in the pictures I take.